Graphenano Composites

Composites with graphene technology

Graphene technology applied to the composites of the future

Industrial innovation in lightweight, strong and sustainable composite materials

Graphenano Composites, a subsidiary of the Graphenano Group, develops and manufactures a complete range of graphene-reinforced resins that deliver much higher performance than traditional composite materials. Our graphene resins (polyester, vinyl ester, epoxy and gel coat) stand out for their:

- High mechanical strength and lightness

- Impermeability and chemical stability

- Improved thermal conductivity

- Bactericidal properties

- Superior durability and reduced microcracking

Thanks to these properties, Graphenano Composites is a leader in the development of advanced graphene composites, applied to key industrial sectors.

Years of innovation and global growth

Turning Graphenano composites into the most competitive in the sector.

Founded in 2012, Graphenano Composites has experienced solid growth thanks to applied research, the use of advanced nanotechnology and the incorporation of new technologies.

Headquartered in Yecla (Murcia, Spain), with industrial presence in Brazil (Diadema, SP) and Germany (Dachau), we distribute our products to companies across Europe, Latin America, the Middle East and Asia.

Industrial applications of graphene composites

We cover the industrial needs of every sector

Thanks to graphene, sectors ranging from construction, naval industry, medical and electronics to the automotive and aerodynamics sector, as well as aeronautics and aerospace, achieve lighter, stronger and more energy-efficient products, contributing to sustainability and process improvement.

Automotive

Construction

Aeronautics and Aerospace

Naval and Railway

Wind and Renewable Energy

High-Performance Sports Equipment

Featured products

Graphene-reinforced resins

We present the different options of graphene resins for various applications.

Discover the graphene products from Graphenano Composites, designed to revolutionise strength and performance in diverse industrial applications. Innovation and superior quality in composite materials.

Poligraph – Polyester resins with graphene

- Types: 140 LV Plus Premium, 140 Plus Premium and 70 Plus Premium.

- Greater mechanical strength, lightness, flexibility, corrosion resistance and durability than traditional resins.

- Applications: manual, pultrusion, RTM, infusion, hand lay-up.

Vinilgraph – Vinyl ester resin with graphene

- Types: 901 LV Plus Premium and 901 Plus Premium

- High thermal, chemical and mechanical resistance.

- Ideal for industrial, marine and chemical storage environments.

- Manual or machine application.

Gelgraph Gel Coat

- Types: Normal and Nautic.

- Resistant to aggressive environments: UV rays, salt spray, abrasion and chemical products.

- Applied manually or by spraying.

Pultrusion with graphene

Next-generation structural composites

At Graphenano Composites, we apply graphene pultrusion technology to manufacture structural profiles and corrugated bars of high performance. Thanks to the use of functionalised graphene, our solutions surpass the limits of conventional composites in terms of mechanical strength, durability, lightness and production efficiency.

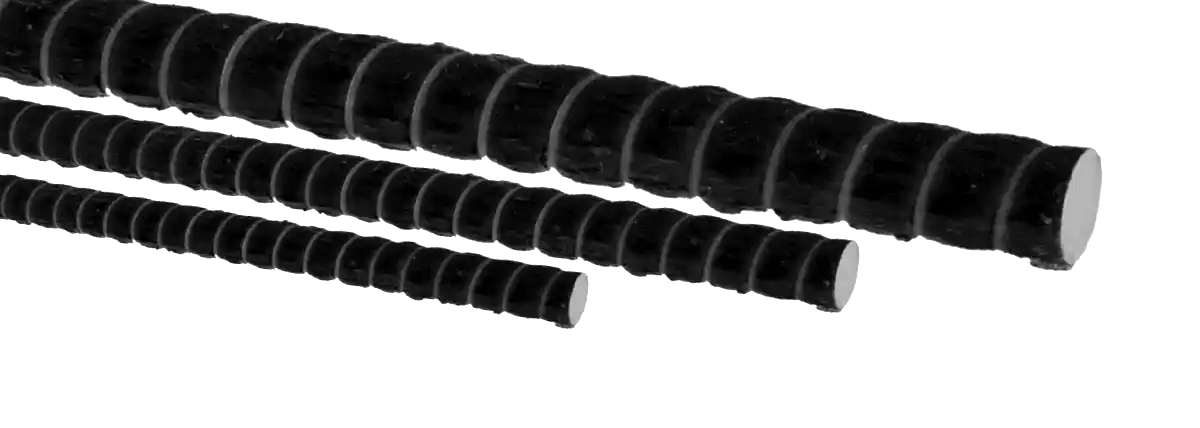

Corrugated bars

Our corrugated GFRP bars with graphene are the ideal solution for reinforcing concrete, replacing steel in environments where higher resistance to corrosion, lightness and durability are required.

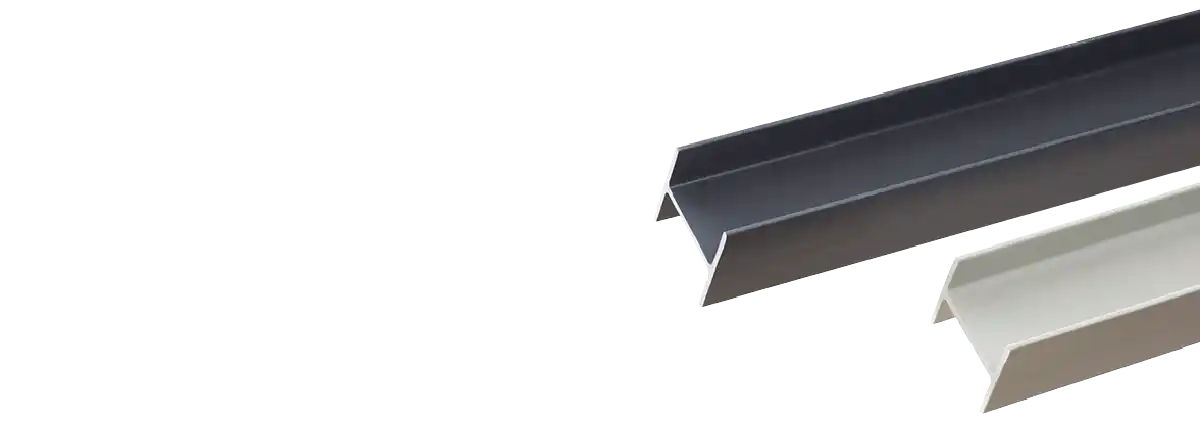

Structural profiles

Our structural profiles reinforced with graphene are designed for applications in sectors such as construction, civil engineering, shipbuilding, aeronautics and the chemical industry.

Quality and industrial performance certifications

Mechanical testing according to UNE EN ISO 14125.

Structural certification in process with TÜV SÜD Iberia.

Fire resistance testing A2-s1, d0 (in progress with AFITI).

Tested in real industrial environments with performance above standard.

Gel coat evaluated to withstand extreme UV, saline and chemical conditions.

Commitment to sustainability and energy efficiency

Our commitment is to offer products that set new benchmarks in sustainability and performance

Graphene composites help reduce structural weight, improve the energy efficiency of products and lower the carbon footprint. In addition, they increase durability and reduce maintenance requirements, which results in lower operating costs and longer lifespan.

Research, development and constant innovation

Since our beginnings, we have embraced R&D&I as a driving force for progress, offering cutting-edge technology in resins and sustainable composites. Our goal is to transform traditional industrial processes through intelligent materials based on graphene, adapted to the current and future challenges of global industry.