Graphenano Dental

Pioneers in graphene nanoreinforced biopolymers.

Advanced dental materials with graphene

Leaders in graphene-doped biopolymers for digital dentistry

Graphenano Dental, a subsidiary of the Graphenano Group, is an international benchmark in the development of advanced dental materials reinforced with graphene.

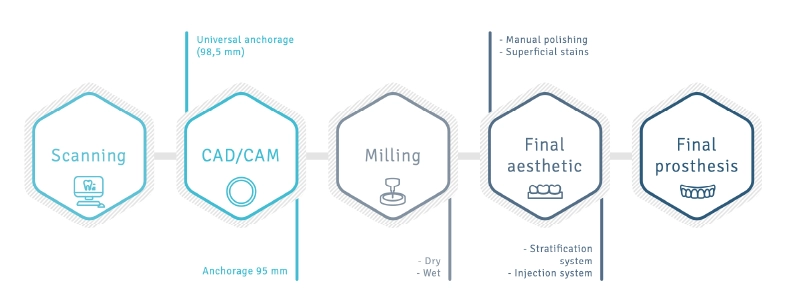

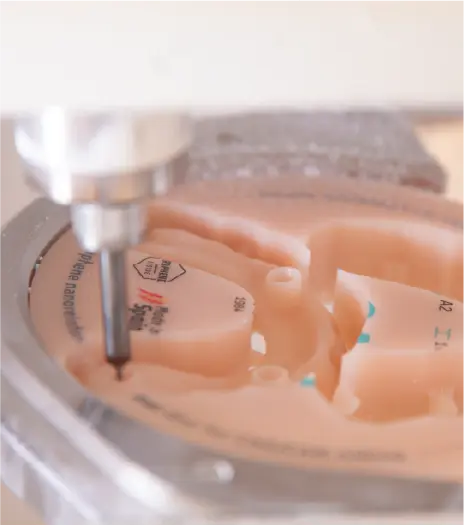

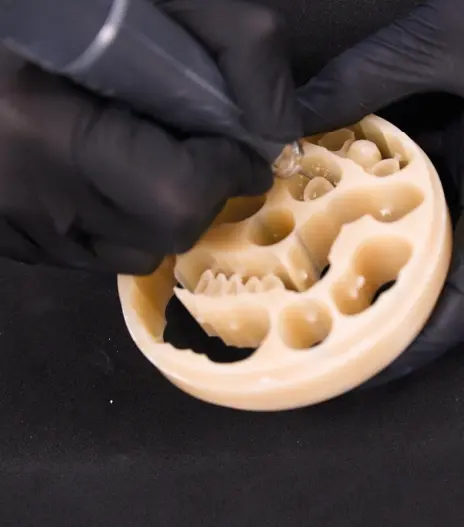

Our technology focuses on the production of graphene nanoreinforced biopolymers such as G CAM, an innovative resin disc doped with graphene, specifically designed for CAD/CAM milling in restorative dentistry.

Improved mechanical properties thanks to graphene

In this way, we transform conventional PMMA into a definitive dental material that offers:

- Ultralight and strong

- Extends the service life of materials

- Superior electrical and thermal conductivity

- Recyclable and sustainable

- Energy and cost savings

This makes G CAM the ideal solution for full dental prostheses, crowns, veneers and implant-supported rehabilitations, eliminating the need for metal structures.

🦷 Constant innovation in dental materials with graphene

Since its foundation, Graphenano Dental has evolved into a complete line of graphene dental products, including:

G CAM:

Graphene disc for CAD/CAM milling, available in multiple colours and thicknesses.

G Print 3D

Graphene-doped resin for 3D printing.

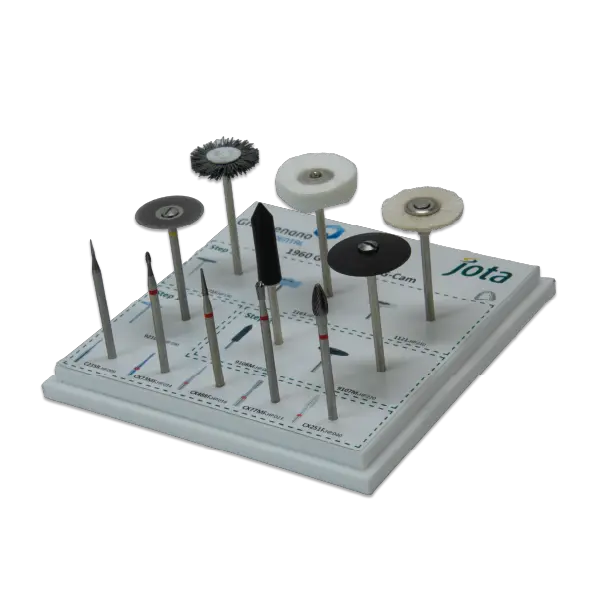

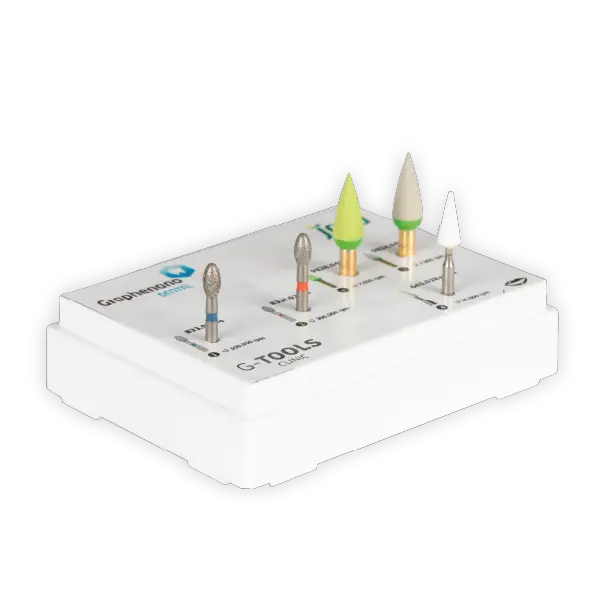

G CAM Polishing Kit

Professional finishing for laboratories.

Clinical Polishing Kit

Adapted to the clinical environment.

G-BLOCK

New versatile format for milling, highly demanded by clinics and laboratories.

International presence and global distribution

We offer direct online sales and a wide network of authorised distributors in more than 20 countries: Spain, United States, Brazil, France, Italy, India, United Kingdom, Australia, among others.

Our global coverage ensures access to high-tech dental materials with graphene in any market.

Origin and productivity

Revolutionising digital dentistry

Graphenano Dental was founded with the mission of revolutionising restorative dentistry through a faster, versatile and efficient material. With G CAM, dental laboratories can triple their productivity: while a traditional prosthesis may take 18 hours, with G CAM the process is reduced to just 3 hours, with no need for sintering or vitrification.