GraphenBar®

Non-corrosive glass fiber reinforcement bars (GFRP)

Innovation in structural reinforcement for more sustainable construction

Lightweight, durable, non-conductive reinforcement for reinforced concrete in demanding infrastructures.

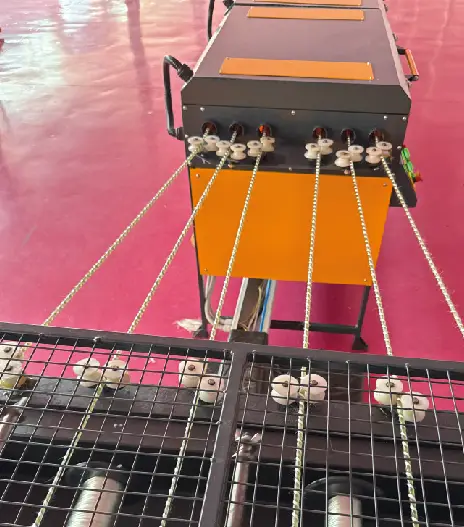

GraphenBar® bars are fiber-reinforced polymer (FRP) reinforcements designed to replace traditional steel in concrete applications.

Thanks to their pultrusion manufacturing using high-performance fibers and specialized resins, they offer up to 100 years of service life, eliminating corrosion problems and reducing environmental impact.

Main advantages of GraphenBar

Beyond steel: benefits that extend the lifespan of your projects.

Durability without corrosion in marine environments, chlorides and aggressive agents

Up to 4x lighter than steel

Which facilitates transportation, installation and logistics.

High performance per weight

And excellent long-term stability.

No electrical or magnetic interference

Lower life cycle cost

compared to steel in aggressive environments.

Lower environmental impact compared to steel

Product ranges

GraphenBar® FiberGlass Epoxy

Reinforcing bars made of fiberglass (GFRP) and epoxy resin, designed to replace steel in reinforced concrete structures. They combine high mechanical strength, light weight, and dielectric stability, making them ideal for bridges, docks, wastewater treatment plants, structures near sensitive equipment, and projects requiring rapid installation and a long service life.

- Available diameters: 6, 9, 10, 12, 14, 16, 18, 20 mm.

Sectors and uses where GraphenBar® fits best

Road, coastal, hydraulic, and underground infrastructure: maximum durability without corrosion and zero interference.

Road infrastructure

Bridges, viaducts, retaining walls.

Maritime and hydraulic works

Dikes, docks, canals, treatment plants.

Civil and industrial building

Foundations, tanks, elements subjected to electromagnetic fields.

Foundations, tanks, elements subjected to electromagnetic fields

Diaphragm walls, soft-eyes, piles and tunnels.

Why switch from steel to GFRP with GraphenBar®

-

+ Service life,

– maintenance in aggressive environments. - + Productivity on site: less weight, fewer personnel for handling, faster installation.

- + Regulatory Compatibility: Designed to comply with ACI 440 and ASTM D7957 (common references in GFRP specification).

FAQs

Ask us anything!

How does GRAPHENBAR compare to steel in terms of strength?

GraphenBar® has a tensile strength greater than 1000 MPa (145 ksi). Compared to steel, GraphenBar® can withstand more than three times the tensile load of steel before failure.

How does the modulus of elasticity of GraphenBar® compare to steel?

GraphenBar® has a tensile modulus greater than 67 GPa (9427 ksi). Compared to steel, GFRP rebar is more flexible, allowing it to absorb seismic energy more effectively due to its improved properties and lower density.

How does the strain of GraphenBar® compare to steel?

GraphenBar® has a tensile strain between 1.5% and 2.5%.

What sizes of graphene fiberglass rebar are available?

Graphene fiberglass rebars are available in standard sizes from 6 mm to 20 mm. Other sizes are available upon request.

How to tie GFRP rebar?

Tie GRP rebar with stainless steel or nylon wire. You can also use zip ties or fiberglass-reinforced tapes. If corrosion or electromagnetic fields are not a concern, regular wire can also be used.

How does the price of GraphenBar® compare to steel rebar and stainless steel rebar?

GraphenBar® costs significantly less than stainless steel. Its price is also lower than that of steel rebar, and when considering all the savings from labor costs, corrosion protection additives, concrete cover, and transportation, the total cost is much lower than that of steel rebar.

What is the end of life of GraphenBar® like?

GraphenBar® is made of fiberglass, which is 100% recyclable, and epoxy resin with graphene. When embedded in concrete, the material can be crushed together with the concrete after more than 100 years, without needing to be removed, and it can become part of the next recycled concrete—making the new concrete much stronger.

Does your project need corrosion-free reinforcement?

Tell us the scope and we will help you choose between GraphenBar® FiberGlass Epoxy (Ø 6, 9, 10, 12, 14, 16, 18, 20 mm) with technical specifications and calculation support.