Gelgraph

High-Performance Graphene Gel Coat

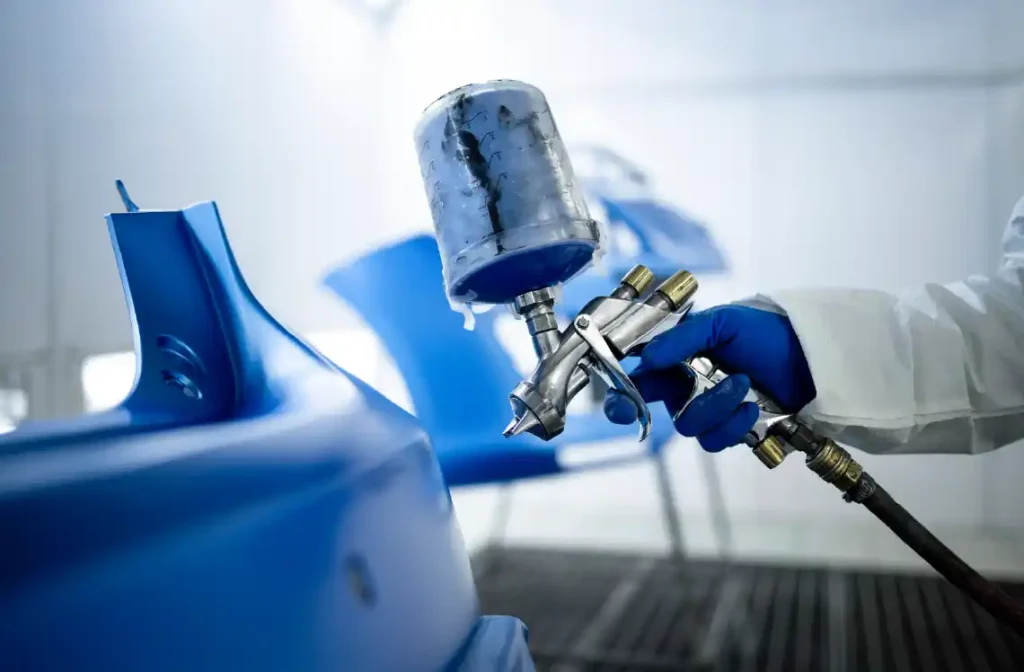

Protection, aesthetics and durability for moulds and technical parts

Gelgraph is a graphene-enhanced gel coat developed by Graphenano Composites, designed to provide advanced surface protection and a superior aesthetic finish for moulds and technical parts manufactured with composite materials.

Thanks to the incorporation of graphene nanotechnology, Gelgraph offers greater thermal, chemical and mechanical resistance, significantly reducing wear and extending the service life of exposed surfaces.

What is Gelgraph?

Gelgraph is a technical surface coating that acts as both a protective and decorative layer for composite parts. Compatible with polyester and vinyl ester resin matrices, Gelgraph is formulated with functionalised graphene, giving it unique advantages over traditional gel coats.

Advantages of our Gelgraph Gel Coat

- Greater thermal resistance and protection against UV rays

- Bactericidal and antimicrobial properties

- Excellent resistance to aggressive chemical agents

- Durability against abrasion and wear

- Reduced surface microcracking

- High-quality aesthetic finish

- Compatible with manual or spray application

- Available in gloss, satin or matt finishes

Gelgraph Gel Coat Range

Discover our different graphene-reinforced gel coats designed to provide tailored solutions.

- Gelgraph Gel Coat ISO Airless

Gel coat based on isophthalic NPG unsaturated polyester resin with graphene, medium–low viscosity.

- Gelgraph Gel Coat ISO Moulds

Gel coat based on isophthalic NPG unsaturated polyester resin with graphene.

- Gelgraph Gel Coat Nautic

Gel coat based on isophthalic NPG unsaturated polyester resin with graphene, specially designed for nautical environments.

Industrial Applications

Gelgraph is ideal for use in sectors requiring resistance, protection and a professional finish, such as:

Naval industry (parts exposed to saline environments)

Construction (technical façades, decorative elements)

Aeronautics and automotive

Technical and industrial furniture

Components exposed to UV radiation and chemical attack

Continuous production moulds

Maximum resistance in extreme environments

Thanks to graphene, Gelgraph provides greater thermal and dimensional stability, even in environments with:

Prolonged solar exposure

Salt fog

Environmental humidity

Industrial chemical environments

These properties make it an ideal gel coat for outdoor use, industrial applications or components that require durability without surface degradation.

Compatibility and Application

Gelgraph can be applied to:

Polyester or vinyl ester resin-based matrices

Metal or composite moulds

Parts manufactured by RTM, infusion or lamination

Application:

Manual: using a brush or roller

Automatic: using a spray gun

Its controlled texture and stable viscosity ensure a homogeneous application without drips or bubbles.

Gelgraph: aesthetics, technology and sustainability

By integrating functionalised graphene, Gelgraph provides greater durability with less maintenance, which:

Reduces the need for repainting or recoating

Minimises exposure to aggressive cleaning products

Extends the service life of components

This contributes to more sustainable projects, with lower operating costs and greater long-term reliability.

With Gelgraph, Graphenano Composites offers a technical coating that protects, enhances and improves any composite part, ensuring a stronger, more resistant and longer-lasting final surface.