FloorGraphene

Graphene-based additive for thermally conductive floors

Improve the energy efficiency of your floors with graphene nanotechnology

FloorGraphene is a graphene-reinforced additive developed by Graphenano Smart Materials, designed to significantly enhance the thermal conductivity of self-levelling mortars and concrete used in underfloor heating systems, technical pavements and industrial surfaces.

This additive creates an internal network of functionalised graphene, ensuring a homogeneous distribution of heat and greater energy efficiency in the construction system.

What is FloorGraphene?

FloorGraphene is a additive based on functionalised graphene, specially formulated for mortar or cement mixes used in:

-

Floors with underfloor heating (electric or hydraulic)

-

Energy-efficient building pavements

-

Industrial or logistics pavements

-

Installations requiring thermal dissipation (technical rooms, hospitals, etc.)

It acts at the nanometric level, enhancing thermal conductivity without altering the workability of the mix, while delivering positive effects on resistance, durability, and curing time of the material.

Benefits of FloorGraphene

- Increase in thermal conductivity by more than 30%

- Reduction in energy consumption of the heating system

- More homogeneous heat distribution

- Reduced surface heating time

- Improved mechanical strength and crack resistance

- High compatibility with traditional application systems

- Suitable for both interior and exterior use

Recommended applications

FloorGraphene is ideal for:

Underfloor heating systems (electric and hydraulic)

Passivhaus homes and energy-certified buildings

Healthcare, sports and commercial centres

Logistics facilities and high-traffic areas

Thermal rehabilitation works for pavements

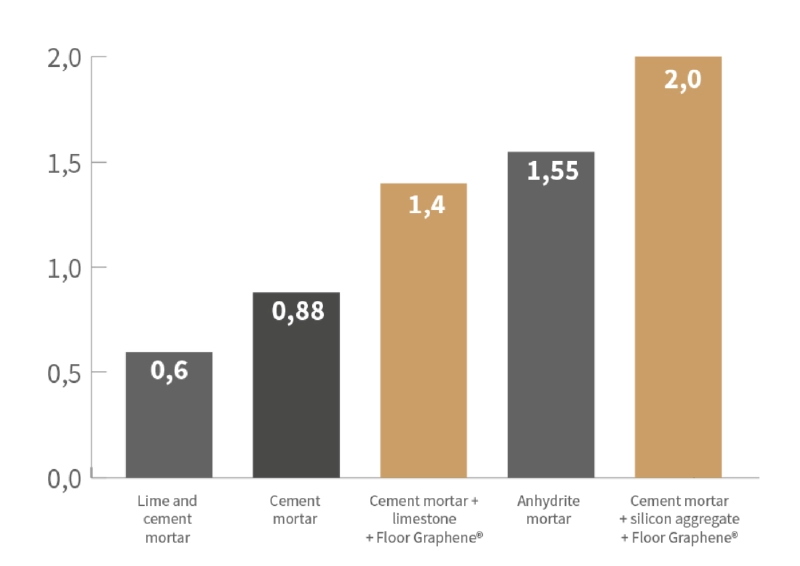

Laboratory-validated results

The tests carried out in technological centres and real installations have shown:

Increase in thermal conductivity up to 1.5 W/m·K (from standard values of 0.8–1.0)

Improvement in flexural and compressive strength

Reduction in curing time and improved mortar cohesion

Compatibility and Use

FloorGraphene is a solution aligned with the objectives of sustainable construction and energy efficiency.

It helps reduce electricity consumption and improves indoor thermal comfort, while also offering:

Compatibility with conventional cements and self-levelling mortars

Direct dosing into the dry mix (on-site or at plant)

No additional machinery or technical modifications required

Can be applied using a pump or traditional system