G-PRINT

Graphene-doped 3D resin for dental models

High precision in 3D printing for digital dentistry

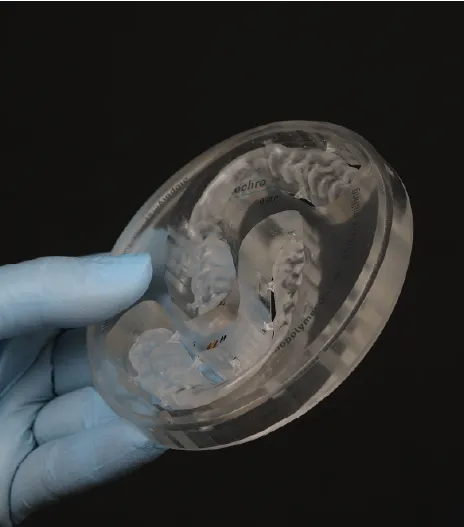

G-PRINT is a 3D printing resin developed by Graphenano Dental, formulated with advanced technology doped with medical-grade graphene. Designed for the manufacture of solid or hollow dental models using DLP printers, G-PRINT offers high dimensional stability, smooth non-porous surfaces and superior accuracy for precise dental restorations.

What makes G-PRINT resin unique?

G-PRINT resin has been developed to meet the demands of dental laboratories and digital clinics, allowing precise and consistent printing with long-lasting durability.

Benefits:

- Excellent visibility of margins and contours (natural tooth colour)

- Easy cleaning and simple handling with conventional plaster

- Humidity and abrasion resistant, avoiding surface adherence

- Printing without shrinkage thanks to its stability and low sedimentation

- Ideal for DLP 3D printers with a 405 nm wavelength

G-PRINT 3D Model workflow

The G-PRINT workflow is fast, simple and reproducible:

1

Design

2

Compatible 3D printer and calibration of G-PRINT resin

3

Prepare the model slice

4

Material required for printing

5

Model printing

6

Cleaning

7

Post-curing

G-PRINT technical parameters

- Hardness: 87 Shore D

- Viscosity (25°C): 552 mPa.s

- Curing wavelength: 405 nm

- Liquid density: 1.1 g/cm³

- Solid density: 1.184 g/cm³

- Elastic modulus (1): 2540 MPa

- Flexural strength (5%) (1): 80.6 MPa

- Exposure time: 0.6 – 5.5 s

- Shelf life: 12 months

🦷 Other dental products

Since its foundation, Graphenano Dental has evolved into a complete line of graphene dental products, including:

G CAM:

Graphene disc for CAD/CAM milling in multiple colours and thicknesses.

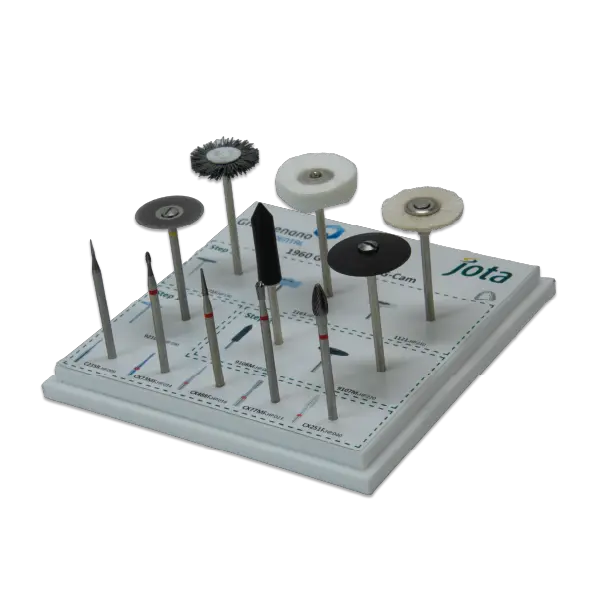

G-CAM Polishing Kit

Professional finishing for laboratories.

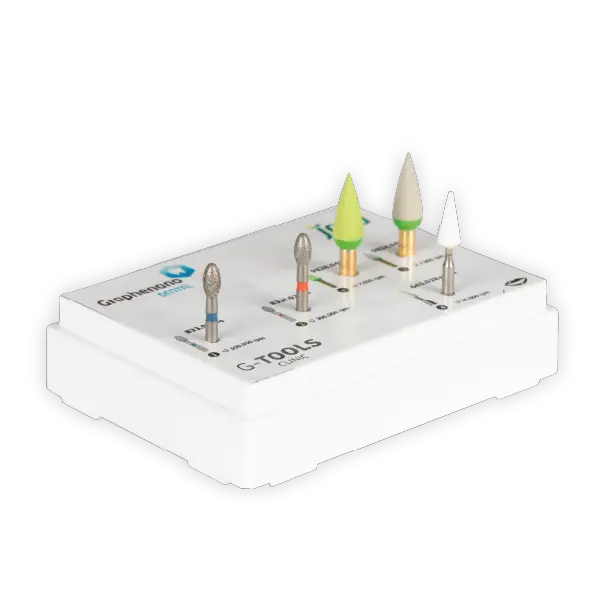

Clinical Polishing Kit

Adapted to the clinical environment.

G-BLOCK

New versatile milling format, highly demanded by clinics and laboratories.